EXPLORE REFERENCE PROJECTS

- Back

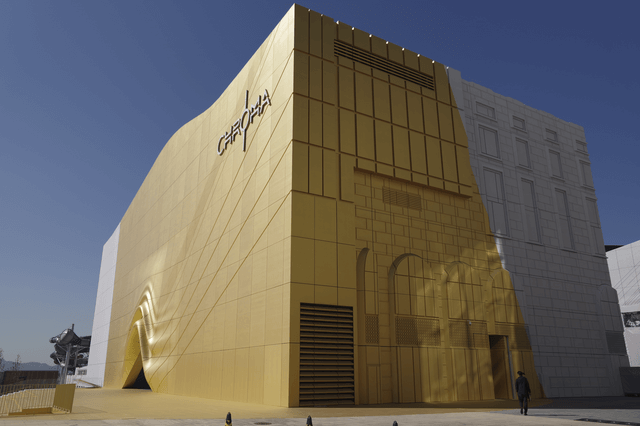

THE IMPRINT, SEOUL, KOREA

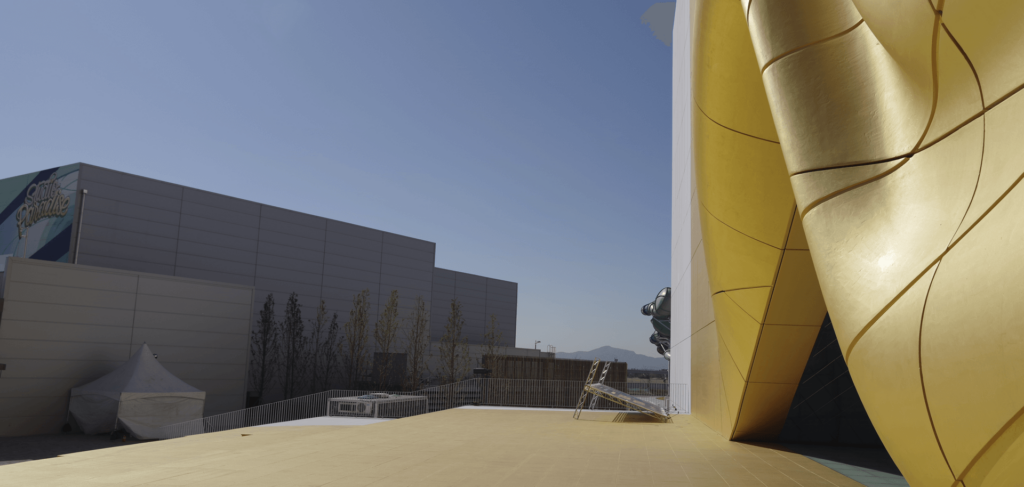

Not far from South Korea’s largest airport Incheon is “Paradise City”, an amusement and entertainment center that was expanded in 2018 with two lustrous new buildings. “The Imprint” houses a nightclub and the “Wonderbox”, an indoor entertainment park. Because both uses do not require natural lighting, it was possible to design without windows and reduce the building volumes to simple cubes. But the architects from MVRDV transformed the cubic idea into a unique staging through a sophisticated precast concrete façade concept.

Project Summary

PROJECT

THE IMPRINT, SEOUL, KOREA

ARCHITECT

MVRDV

Photo Credit

Tec-Wall-Korea Co. Ltd.

Completed

2018

PRODUCTS

SHIMMERING GOLD

Strictly speaking, the glass fiber reinforced concrete curtain panels form an independent layer, which takes its structures and forms from the immediate surroundings. Windows, arches, squares and doors do not really exist, they are only present in relief and remain basically blind and with no function.

What is interesting is that the relief has been inverted, the joints of the stone ashlar rise upwards from the flat surface. The Korean facade constructor Tec-Wall produced and installed 3869 different modules to make the dummy facade. But MVRDV did not stop there and topped everything with a theatrical gesture.

The architects have not used conventional entrances. Instead, the facade is raised like a curtain held in place by unknown forces. An entire corner of the building looks particularly impressive as it morphs upwards, with the line of the eaves rising accordingly. And where the facade rises out of the ground, the lighting effects catch the eye as they shift colors playfully. Almost all the VHF panels were given a white coating after they had been installed.

WHERE THE CURTAIN RISES

The client was so enthusiastic about the idea of the airy curtain and the relief that they wanted to emphasize the artistic approach even more. The result is golden: The nightclub cube was given a luminous coating of KEIM Mineral Metallic Finish in pure gold. This mineral-based finish was specifically designed for the extreme weather, as well as being durable, lightfast, water-repellent, vapor-permeable and it produces a matte, velvety surface. In other words, it has a quality that visually underlines the effect of the golden pigmentation: a soft shimmer covers the curvaceous shaped facade, which placed very special demands on how the paint was applied. After all, the large number of joints, folds and curves as well as the decorative elements were supposed to present the appearance of a uniform, all-encompassing color. Almost all the paint was applied using a roller directly onto the concrete panels, which partially levelled the surfaces before the final coat of metallic paint. Joints were smoothed out with special joint brushes; in most cases, the large number of projections and recesses and the three-dimensional shape of the base structure required masterful craftsmanship.