MINERAL-ART™ MURAL PAINTS

LONG-LASTING,

PERMANENT COLOR,

PAINTS AND STAIN/GLAZES.

KEIM.

Courtesy of Guido Van Helten

Mineral silicate paints

outlast latex and acrylic

paints.

By decades.

Artists have been choosing Keim for over 140 years to decorate some of the most important historic masonry in the world. You, too, can select mineral silicate paints renowned for their durability and longevity. These paints penetrate and form permanent bonds with concrete and masonry, and the finishes are extremely vapor permeable, which makes them ideal for painting such surfaces. The earthen mineral colors used in these paints are inert and defy UV, meaning they do not fade or change colors over time.

MINERAL PAINTS ARE TRULY EXTRAORDINARY

See what makes mineral silicate paint long-lasting?

Will not flake or peel

MINERAL PAINT FUSES CHEMICALLY WITH BRICK, STONE, STUCCO, CONCRETE AND MASONRY

KEIM is the perfect solution for those who want a long-lasting and beautiful finish for their home or building. Unlike traditional paints, KEIM paint forms covalent chemical bonds with masonry to ensure lasting, permanent adhesion. This unique process, called petrification or silicification is very similar to the bonds that form limestone in nature to ensure paint cannot peel or flake off. Mineral paints become “part” of the masonry for decades of durability.

SOLID MINERAL COMPOUND

Silicification is a geological process that replaces original materials with silica. The process involves silica-rich binder, the backbone of KEIM paint, penetrating and seeping into voids in masonry. The binder dissolves calcium carbonate, which precipitates silica. The silica, or quartz, results in the mineralization, “turning to stone” of wet paint.

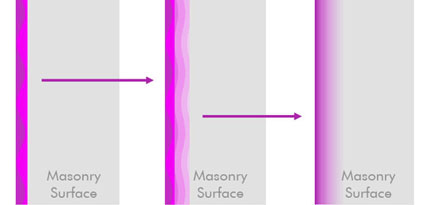

- LEFT: Mineral silicate paint is applied to masonry like ordinary paint.

- MIDDLE: The binder seeps deep into masonry and begins the chemical process.

- RIGHT: Cured paint is now an integral part of the masonry surface with a colored microporous crystalline matrix surface.

Typical latex/acrylic paints adhere to the surface by a sticky mechanical bond, while KEIM mineral silicate finishes penetrate and form permanent, chemical bonds. You will never experience the situation pictured here.

Will Not Flake or Peel

Defies severe weather

MINERAL PAINTS REPEL WINDDRIVEN RAIN

Proven by third-party ASTM standard testing, KEIM mineral paints completely resist winddriven rain without leaking, ensuring moisture cannot penetrate. The stone-like surface is naturally hydrophobic, with no capillary action to draw moisture into walls. Keeping water away from masonry walls is key to longevity and low maintenance.

MINERAL PAINTS ARE NOT DEGRADED BY EVEN THE HARSHEST UV

Quartz binders, the “glue” that binds mineral paints and pigments, like their namesake minerals are not deteriorated by sunlight or UV. From high mountain to desert climates, mineral paints stand the test of time. KEIM mineral paints are a favorite of lighthouses across the globe for their durability, low maintenance, and true colors.

Defies Severe Weather

Colors do not fade

The surface of mineral paint resembles that of stone and is inert, making it impervious to various environmental factors such as UV, wind, rain, freezing temperatures, and acid rain. The paint finish, comprised of mineral silicate binder and mineral pigments and fillers, ensures no degradation from even the severest weather, thus resulting in an extraordinarily long life.

And KEIM offers a 20-year guarantee not to fade or lose adhesion.

KEIM Origins

“Gasthaus Weißer Adler” in Stein am Rhein, Switzerland was one of the first to be painted with KEIM mineral paint in 1891. It has endured and has never been repainted.

Wikipedia, 2020

KEIM IN THE USA SINCE 1905.

KEIM has been providing paint in the USA since 1905. The Jupiter Inlet Lighthouse and Museum in Jupiter Island, Florida, is one of the first known paint projects in the US. According to records, Keim mineral paint was first used to paint the brick lighthouse in 1905 to improve visibility and protect the historic brick from the harsh coastal climate. The standard KEIM red color was used, proven to be enduring as it survived for over a century without fading. It was repainted in the 1960s and again in 2019 to protect it for another 30 to 50 years. Can you imagine a red exterior paint color

Colors Do Not Fade

Healthy materials

MINERAL PAINTS CONTAIN LESS THAN 5% ADDITIVES

Consider a paint with complete transparency to natural ingredients—KEIM mineral silicate paints are comprised of what you see here. Potassium silicate (liquid quartz), mineral pitments, titanium dioxide, and feldspar— natural quartz comprising more than 95% of the total ingredients.

No plasticizers or other plastics, no biocides, no VOC’s and no harsh chemicals. Allergy sufferers will find KEIM paints a breath of fresh air with no odor or outgassing of toxins. Once the water has evaporated from the wet paint, no other chemicals are outgassed.

And our ingredients are fully vetted by multiple third party testing and certification agencies:

- UL Greenguard Gold

- Cradle to Cradle Product Institute

- The International EPD System

ALL KEIM PAINTS ARE CERTIFIED GOLD FOR MATERIAL HEALTH

With their natural, safe, and non-toxic ingredients, KEIM paints and stains are certified Gold for Material Health by the Cradle to Cradle Product Institute®.

- Potassium carbonate and water are the chief ingredients—no harmful chemicals.

- Minerals are odorless—in the container and on your walls.

- Truly VOC free—no solvents are ever added.

- Experience the peace of mind that comes with knowing that KEIM paints and stains contain only naturally occurring minerals, fillers, and pigments. No biocides, plasticizers, or harsh chemicals are used, ensuring a truly eco-friendly product.

- Pure—KEIM finishes are safe and nontoxic, tested for over 10,000 harmful chemicals and solvents.

Healthy Materials

Paint that breathes

NO PAINT IS MORE VAPOR PERMEABLE THAN MINERAL PAINTS

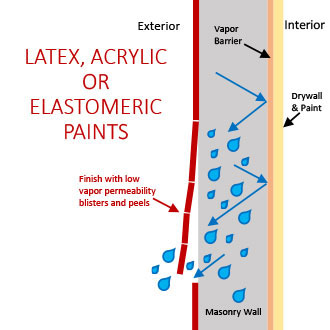

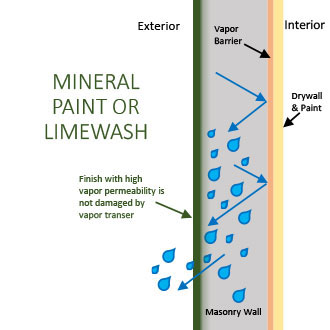

Imagine a paint finish that allows your masonry walls to breathe naturally. Ordinary latex/acrylic paints seal masonry surfaces with a plastic layer that can trap moisture inside walls. KEIM mineral paints are microporous, allowing moisture to pass freely without damaging the paint.

Keeping masonry walls drier is critical to longevity and lower maintenance.

KEIM mineral paints will never blister. This latex/acrylic paint was installed on concrete, and trapped moisture is bubbling the paint and damaging the concrete beneath.

Latex/Acrylic VS KEIM Mineral Silicate

Moisture inside masonry or concrete walls is inevitable, but walls should dry out quickly to avoid mold surface damage, bubling paint, and deterioration of the wall itself. Here is an illustration of the difference between typical latex and acrylic paints and mineral paints

LEFT: Latex/Acrylic paints are made from petroleum and are considered nonbreathable. Trapped moisture cannot escape and builds behind the paint layer, ultimately pushing it from the surface.

RIGHT: Mineral paint is microporous and is completely breathable—moisture vapor escapes freely, without harm leaving masonry drier and healthier.

Paint that Breathes

Paint will not burn

MINERAL PAINTS ARE CLASS-A BUILDING MATERIALS

Mineral paints, such as KEIM mineral silicate paints and stains, are considered Class-A building materials because they are inert and won’t burn, making them safe in the event of a fire. ASTM E 84-08 testing shows that mineral silicate paints have a flame spread index of zero and a smoke-developed index of <5, which is the best performance for a paint surface.

This is because the components of these paints, including mineral silicate binders, quartz fillers, and mineral pigments, do not burn and do not provide fuel for a fire. On the other hand, latex, acrylic, and elastomeric paints, despite being waterthinned, are petroleum-based and their resins can burn and provide fuel in the event of a fire.

Paint Will Not Burn

Sustainable materials

Sustainability is a pivotal consideration in discussions about the future of construction. The building sector significantly contributes to greenhouse gas emissions, with 37% of global emissions coming from this industry, mainly from material production. KEIM mineral paints are specifically engineered to conserve natural resources, minimize waste, and reduce energy consumption. Let’s delve into how mineral paints contribute to sustainable practices:

- Mineral paints are exclusively made from renewable and abundant earthen materials, such as potassium carbonate,

quartz, and mineral pigments. - KEIM’s manufacturing process unequivocally demonstrates its unwavering environmental commitment by using solely renewable energy and recycling all water, resulting in a significantly reduced environmental impact.

Mineral paints are low-carbon-emitting products that actively consume CO2 during the curing process. - All suppliers undergo rigorous vetting and certification to ensure compliance with local guidelines and laws regarding material extraction, safety, and ethical treatment of workers, with a strict prohibition on the use of child or slave labor.

- KEIM’s paint formulas are impeccably optimized for a circular economy and necessitate no specialized processing for disposal.

Sustainable building materials provide a way to conduct environmentally responsible construction practices. This helps promote resource conservation and reduce carbon emissions. KEIM mineral paints offer durability, energy efficiency, low-maintenance, and aesthetic appeal. Embracing sustainable building materials in construction projects can help create a greener future while providing healthy and comfortable living spaces for inhabitants.

The construction industry must urgently do better to protect the environment. This is, after all, the only planet we can live on, so promoting sustainability will serve us — and future generations-in the most crucial way.

KEIM and construction pros are already taking steps in the right direction. Builders are now exploring sustainable construction materials to traditional materials, many of which are a significant source of emissions.

Sustainable Products

MINERAL-ART SELECTION GUIDE

DESIGNED TO MAKE YOUR NEXT MURAL PROJECT AS EASY AS 1—2—3

- Select a base coat: mineral base coats create a beautiful backdrop and uniform surface to paint—creates a mineral “canvas” to paint on

- Select a paint or stain/glaze: two kinds of artist paints for any need

- Soldalit full-bodied, thick paints

- Design Lasur/Stain Glaze, thin-bodied transparent color for watercolor effects

- Select a clear protective finish if desired

STEP 1: Base Coat provides a mineral “canvas”

| Exposure | Product/Description | Where to UsePoints | Color RangePoints |

|---|---|---|---|

| Interior | Innostar Interior Mineral Paint Creates a uniform porosity, mineral and high hiding colored surface or “canvas” for murals |

New or previously painted plaster, drywall, concrete, masonry, etc. | White and a full range of tinted colors |

| Interior + Exterior |

Sanded bonding primer for a slight texture. Fills small cracks and voids up to 1/32” |

New or previously painted masonry, concrete, stone, stucco, etc. where rough surfaces need to be filled | White—not a weathering finish (must be painted) |

| Exterior | Creates a uniform mineral base layer for murals |

New or previously painted masonry, concrete, stone, stucco, etc. | White and full range of monochrome and blended colors |

Step 2: Artist Paints and Stain/Glaze

| Int/Ext | Heavy bodied paint for one-coat coverage and hiding. Stays in place and resists runs and sags. |

New or previously painted plaster, drywall, concrete, masonry, etc. and mineral base coat layer | White and full range of monochrome and tinted colors |

| Int/Ext | Thin-bodied stain/glaze for watercolor effects, from full-color to transparent—your choice. Ideal for shading and blending highlights. |

New or previously painted plaster, drywall, concrete, masonry, etc. and mineral base coat layer | White and full range of monochrome and tinted colors. Use as a solid color or dilute for added transparency. |

| Int/Ext | Clear dilution/thinner to make Design Mineral Stain more translucent |

Add to Design Stain to add transparency | Clear |

| Int/Ext | Shimmering metallic finish that won’t tarnish or fade. |

Use for same surfaces as above | Wide range of metallic colors |

Step 3: Clear Protective Finish

| Interior + Exterior | Clear finish that consolidates aged mineral surfaces and paint for extended durability |

Consolidate bare, sanding masonry and refurbish previous mineral painted surfaces | Clear, matte flat |

| Interior + Exterior | Faceal Oleo HD Permanent Clear Protective Finish Matte flat, clear graffiti protection |

All mineral/masonry surfaces and mineral paints and stains | Clear, invisible |

| Interior + Exterior | PSS 20 Reversible Graffiti Finish Clear sacrificial graffiti protection with a slight sheen |

Bare masonry and mineral painted surfaces | Clear, satin sheen |

EXPLORE OUR MINERAL PAINTS, STAINS AND GLAZES

CONTACT PLUS®

Bonding Primer

Exterior sanded primer for filling cracks up to 1/32 inch, repairing aged, and sanding concrete and masonry. It provides a pleasing overall “lightly” textured surface to improve the aesthetics of older masonry without altering vapor permeability. Use on bare or previously acrylic-painted surfaces.

SOLDALIT® EXTERIOR PAINT

Monochrometöne Colors

Our very best interior/exterior sol silicate full-bodied paint for any mineral surface. It self-primes on bare and previously acrylic-painted surfaces. Application properties are excellent, providing a smooth, perfect, vapor-permeable finish. For the artist, it is available in monochrome and tinted colors.

DESIGN LASUR Transparent Stain/Glaze

Monochrometöne Colors

Sol silicate thin-bodied stain and glaze for transparent colors and water-colored effects. For best results, use over a base coat of mineral primer or paint. It can be mixed with Design Fixative Clear to make colors more transparent. For the artist, it is available in monochrome colors, tinted colors, and metallic glazes.

CONCRETAL® BLACK

Ultra-black Paint for Concrete

Pure black aesthetics for concrete that is guaranteed not to fade. Utilizing a highly specialized inorganic black pigment, for the deepest, purest black color. For the artist, use to create “negative” space in murals and artwork.

INNOSTAR®

INTERIOR PAINT

Sol silicate mineral interior paint for use on masonry, drywall or plaster. Available in a wide range of tinted colors, it provides an excellent mineral base for artwork on a grand scale.

DESIGN METALLIC FINISH

Interior/Exterior Transparent Metallic Finish

This unique metallic flat finish can be used both indoors and outdoors as a transparent glaze or full-hiding metallic colors on interior drywall, plaster, and various types of masonry. It offers a lustrous shimmer that will not tarnish and is available in a wide range of metallic colors. Use it to create a variety of metallic decorative paint effects or to impart sparkling metallic finishes to large surfaces.

Healthy,

Climate Positive,

Equitable Made.

Sustainable Design is Non-negotiable.

Keim paints are certified Silver by the Cradle to Cradle Products Innovation Institute and Gold for material health. Trust Keim to deliver the most sustainable and eco-positive paint and stain options. Period.

Additional Resources

MINERAL PAINT RADIATES LIGHT

An overlooked aspect of mineral paints is their unique interaction with sunlight. The rich, radiant mineral colors and the microporous crystalline surface are dazzling in the morning light and take on a soft glow in the evening.

Here, Soldalit sol silicate exterior paint’s monochrome-tone colors can be seen in photographs taken in the morning at left and near sunset at right. The subject is a mural in Buffalo, NY, called “Golden Hour,” inspired by the colors in the hour before the sun sets.