SOLDALIT® COOLIT

Sol-silicate all surface mineral finish

Introducing SOLDALIT® Coolit – a Sol-silicate All Surface Mineral Finish used to reduce solar heating on masonry surfaces, especially in dark color tones. Soldalit uses a proprietary formula combining silica-sol and potassium silicate binders, inorganic mineral pigments and fillers, and an acrylate copolymer to form both chemical and mechanical bonds, even on the most difficult to paint substrates, without primer coats. This new-generation mineral silicate paint is ideal for finishing ceramic glazed tile and terra cotta, glass, non-ferrous metals, granite, marble, pebble-dash concrete, and previous acrylic or latex-painted surfaces. It is also ideal for all masonry surfaces exposed to severe weather conditions. Tenacious adhesion is enhanced with Soldalit’s nanoparticle technology that allows penetration of even the densest mineral or masonry substrates and provides a mechanical anchor to most existing organic, latex, or acrylic paints in sound condition.

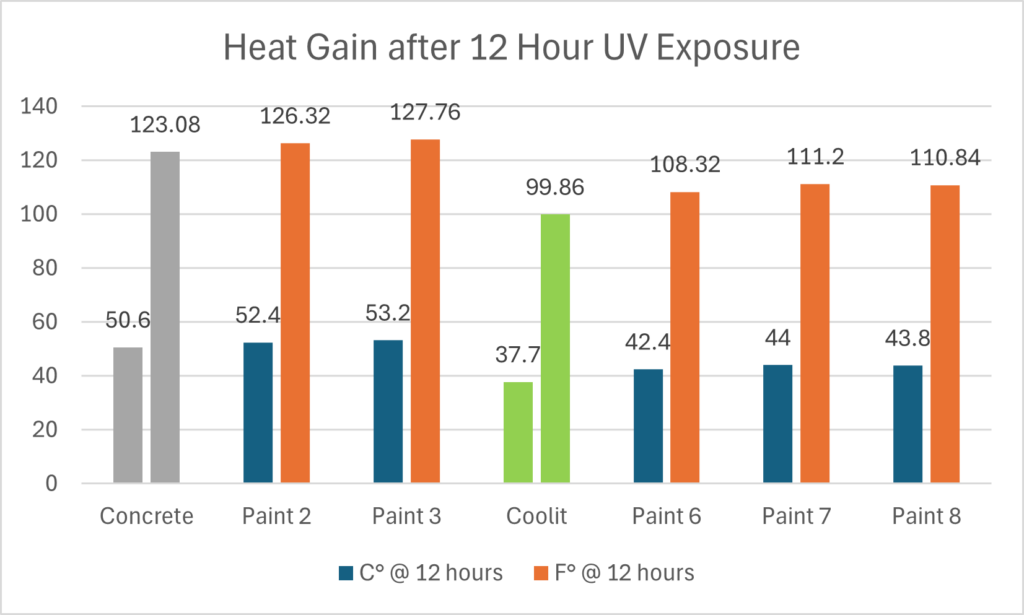

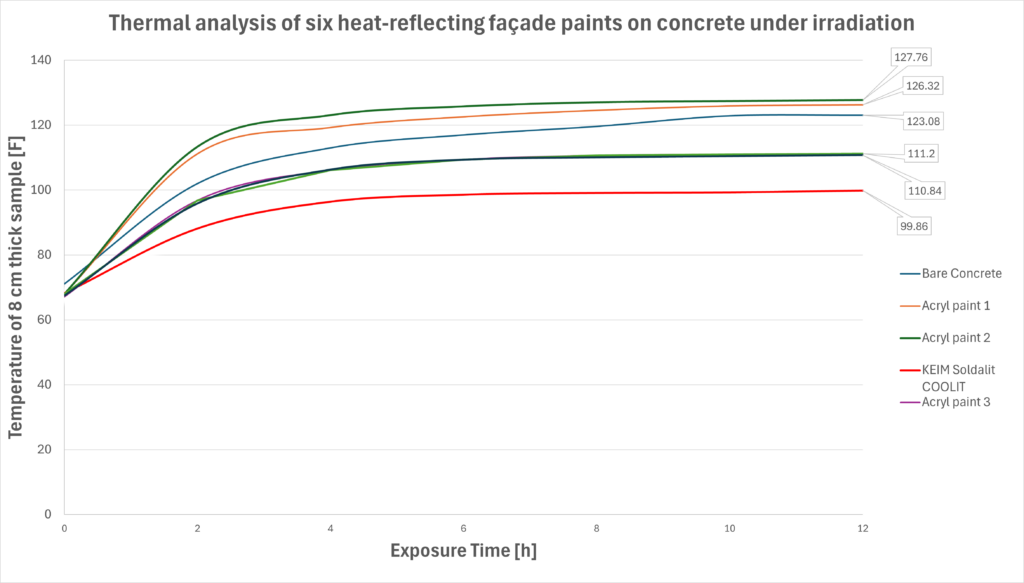

Average following tests. Third-party laboratory testing proves Soldalit Coolit performs best with the lowest temperature. Graph above demonstrates bare concrete panel at left along with two traditional acrylic paints, then Soldalit Coolit and three traditional acrylic paints with IR pigments, all tinted to RAL7043, a dark gray color. Temperature readings after 12 hours of UV exposure. The following graph shows details of temperature evolution as a function of exposure time.

The GWP laboratory conducted an experiment to compare heat-reflective facade paints by KEIM- with other products, aiming to show that KEIM Soldalit COOLIT paint can dissipate and attenuate heat, resulting in a lower surface temperature. All samples were painted with RAL 7043, a dark gray color.

Concrete slabs (30 x 30 x 8 cm) were heated with an OSRAM Siccatherm 250 W infrared heater to approximately 131 °F, at a room temperature of 69.8 °F. Temperature measurements were taken at the surface, 10 mm, and 70 mm depths using NiCr/Ni thermocouples, recorded every 60 seconds over 12 hours. The test included various acrylic facade paints and KEIM Sodalit-IR, all in RAL 7043.

Benefits

- Unique mineral oxide IR Reflective pigments for lower heat gain in high UV environments

- Sol-Silicate binder system penetrates masonry and chemically bonds— won’t peel or lose adhesion

- Copolymer modification provides mechanical bond to previously painted surfaces (as outlined)

- Energy Efficient Coolit Technology

- Lightfast mineral pigments— guaranteed not to fade or lose brilliance

- Apply to a variety of mineral surfaces

- Very water vapor permeable, microporous

- Completely resistant to pollution

- Provides extreme weather resistance and water repellency

- Noncombustible

- Beautiful, mineral matte finish is very natural in appearance and darkens when wet from rain

- Anti-static, inert finish—won’t attract or trap dirt or dust for walls that stay cleaner

- Naturally mold, algae and fungus resistant

Use for

- Concrete and cementitious patches (all types)

- CMU block

- Masonry (brick and stone) and stucco

- Previously Painted Mineral Surfaces

- Hard, glossy mineral surfaces and terracotta

- Patched, cracked and irregular mineral surfaces

Product details

Explore the Modern Desert Colors

Voc

Zero

Color

Select colors that are unique formulated with IR Reflective Oxide Pigments—not all colors are available.

Application

Brush, roll, or airless spray

Coverage

275-325 SF/GAL on cast or pre-cast concrete. See tech data for more information

Packaging

Quart, 1 and 4 Gallon

Sheen

Gloss at 85° - 0.5 Mineral Matte Flat