Specifying Raw and Unfinished Concrete

Today, the use of architectural grade, raw and exposed concrete features is extremely popular with clients, architects, designers and

specifiers. This creates the demand for high quality cast concrete columns, soffits and other surfaces to meet standards for both

strength of concrete and visual finish and color. In addition to design aesthetics, the use of exposed concrete allows the thermal

mass of the concrete to help control heating and cooling, making it both efficient and sustainable.

Of course, due to the inherent variable nature of concrete and the limitations of concrete construction practices, variations in texture,

color and appearance often occur, despite effective specification, planning and execution. This can result in mechanical treatments,

cleaning or blasting and needed repairs that may deliver an unacceptable final appearance.

Concretal® Pigmented Mineral Stain for Concrete

Concretal stain is the ideal solution for unifying uneven or variable concrete finishes and can be used to ensure that the required

finish can be delivered to the client’s or specifier’s standard, without looking like a painted surface. The translucent mineral silicate

stain’s remedial applications are only a small part of their design versatility, as it also offers a wide range of colors to decorate

concrete, without changing the raw concrete’s texture and finish.

Think of this as a color wash specifically developed for concrete surfaces. It is diluted using a complementary Concretal Dilution, at

different ratios, delivering a wide range of opacities to achieve the required color and coverage. All this is done without creating a

“painted” appearance. The system can also be employed to minimize unsightly repairs, blemishes and color variations in the

concrete itself in new installations or in renovated concrete.

Concretal stain penetrates and chemically bonds within the concrete surface creating a microcrystalline structure which allows the

free passage of moisture vapor, and will not inhibit heat transfer for thermal mass purposes. It is highly light refractive, even a

strongly diluted application will increase the light reflection of the concrete, brightening spaces using both natural and artificial light.

Ideal for use in lower light spaces like garages, tunnels, below grade transit stations, etc.

And colors are completely lightfast, no matter how extreme the exposure. Engineered using only natural earthen oxide pigments,

which are not affected by U.V. light, ensures color stability throughout its long lifetime. Concretal systems will never fade, peel or

blister off the surface.

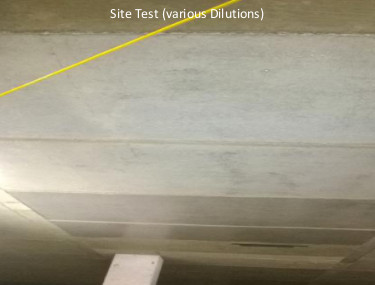

On-site Trials Ensure Results

In order to achieve the best individual result for any project, it is essential to conduct on-site trials and mock-ups to determine the

correct color shades and opacities. This process ensures that each application is unique to the project and ensures the best possible

results. It is sometimes necessary to install Concretal Stain at various opacities across large projects to achieve the most uniform

overall appearance as the final color appearance is a combination of the stain’s impact and the surface color and texture.

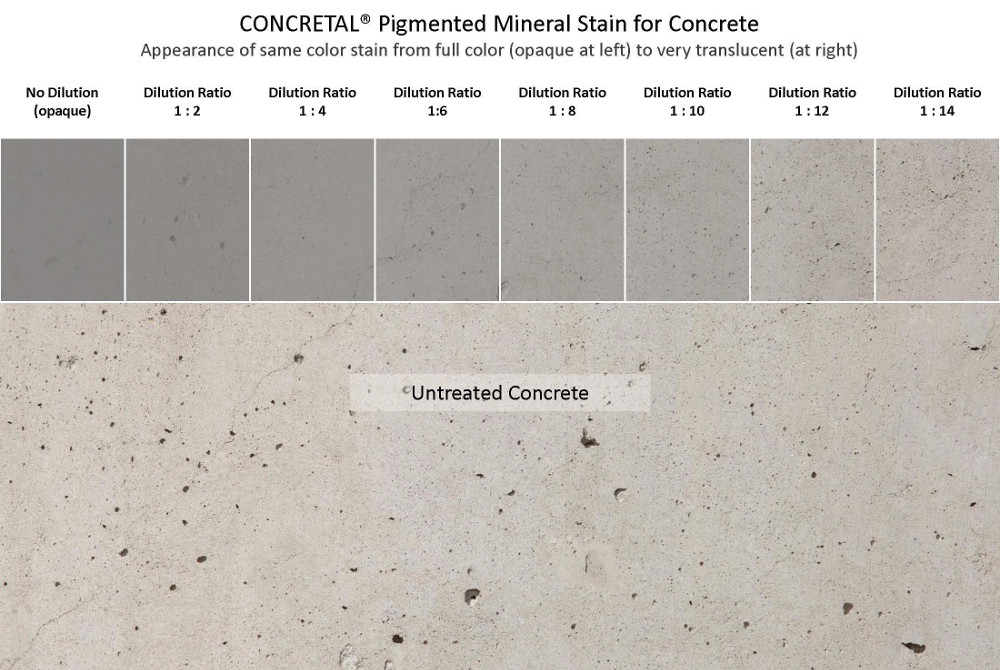

Infinite Control of Color and Transperancy

Concretal Stain is supplied as completely opaque color. To determine how translucent the stain will be applied, a ratio of Concretal Stain

is mixed with Concretal Clear Dilution. This ratio is expressed in terms of 1 part stain to “X” parts Dilution. See the image below for a

demonstration of how the stain varies in transperancy at various dilution ratios.